Laser Texturing Performance for Metal Surfaces

This technical paper reports the texturing speeds obtained during tests by Laserax using a 500W LXQ-HP laser texturing system. Texturing speeds were measured at different power levels for typical levels of surface roughness (Ra) required for metals like steel and aluminum.

The LXQ-HP series includes laser texturing systems developed and manufactured by Laserax, offering laser power up to 500W. The system’s parameters can be modified to generate different roughness levels and patterns.

Surface texturing

Laser texturing is used to prepare and texture surfaces. This technology is highly precise and can either be fully or semi automated. By modifying the roughness of metal surfaces, laser texturing can:

- increase adherence prior to applying coatings or adhesives

- increase the lifetime of paint and coatings

- increase wettability

- increase/reduce electrical and thermal conductivity

- increase/reduce friction

Laser texturing is also a great alternative to abrasive blasting treatments like grit blasting and shotblasting, offering a series of advantages:

- No abrasive media

- Lower operation cost

- Lower maintenance

- Cleaner

- Safer

- Easily automated

Surface cleaning

The same laser system can be used to clean and prepare the surface for laser texturing, removing contaminants such as paint, oxide, dust, rust, mill scale, and so on.

Texturing speeds

The texturing speed of a laser system is affected by three key factors: the desired roughness level (Ra), the laser power, and the textured material.

The tables that follow report texturing speeds for common alloys.

| 100 W | 200 W | 300 W | 500 W | |||||

|---|---|---|---|---|---|---|---|---|

| (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | |

| 3µm / 120µin | 2 - 3 | 0.3 - 0.5 | 4 - 8 | 0.6 - 1.2 | 5 - 12 | 0.8 - 1.9 | 7 - 20 | 1.1 - 3.1 |

| 6µm / 240µin | 1 - 2 | 0.2 - 0.3 | 3 - 5 | 0.5 - 0.8 | 4 - 8 | 0.6 - 1.2 | 6 - 12 | 0.9 - 1.9 |

| 12µm / 480µin | 0.4 - 1 | 0.1 - 0.2 | 1.2 - 2 | 0.2 - 0.3 | 1.8 - 4 | 0.3 - 0.6 | 3 - 6 | 0.5 - 0.9 |

Texturing speeds for Aluminum 6061 - (cm2/s)

| 100 W | 200 W | 300 W | 500 W | |||||

|---|---|---|---|---|---|---|---|---|

| (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | (cm2/s) | (in2/s) | |

| 3µm / 120µin | 2 - 9 | 0.3 - 1.4 | 4 - 17 | 0.6 - 2.6 | 6 - 25 | 0.9 - 3.9 | 9 - 42 | 1.4 - 6.5 |

| 6µm / 240µin | 2 - 6 | 0.3 - 0.9 | 4 - 9 | 0.6 - 1.4 | 5 - 13 | 0.8 - 2.0 | 8 - 21 | 1.2 - 3.3 |

| 12µm / 480µin | 1 - 2 | 0.2 - 0.3 | 2 - 4 | 0.3 - 0.6 | 3 - 7 | 0.5 - 1.1 | 4 - 10 | 0.6 - 1.6 |

Texturing types

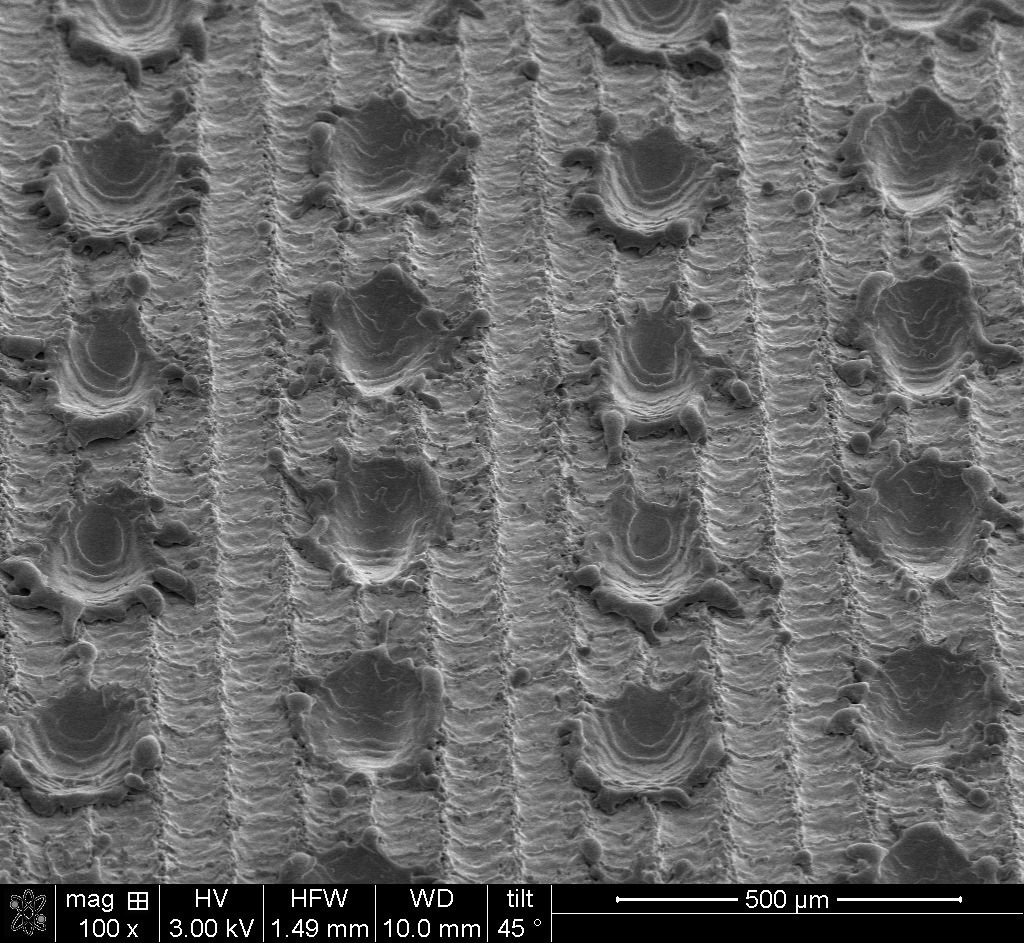

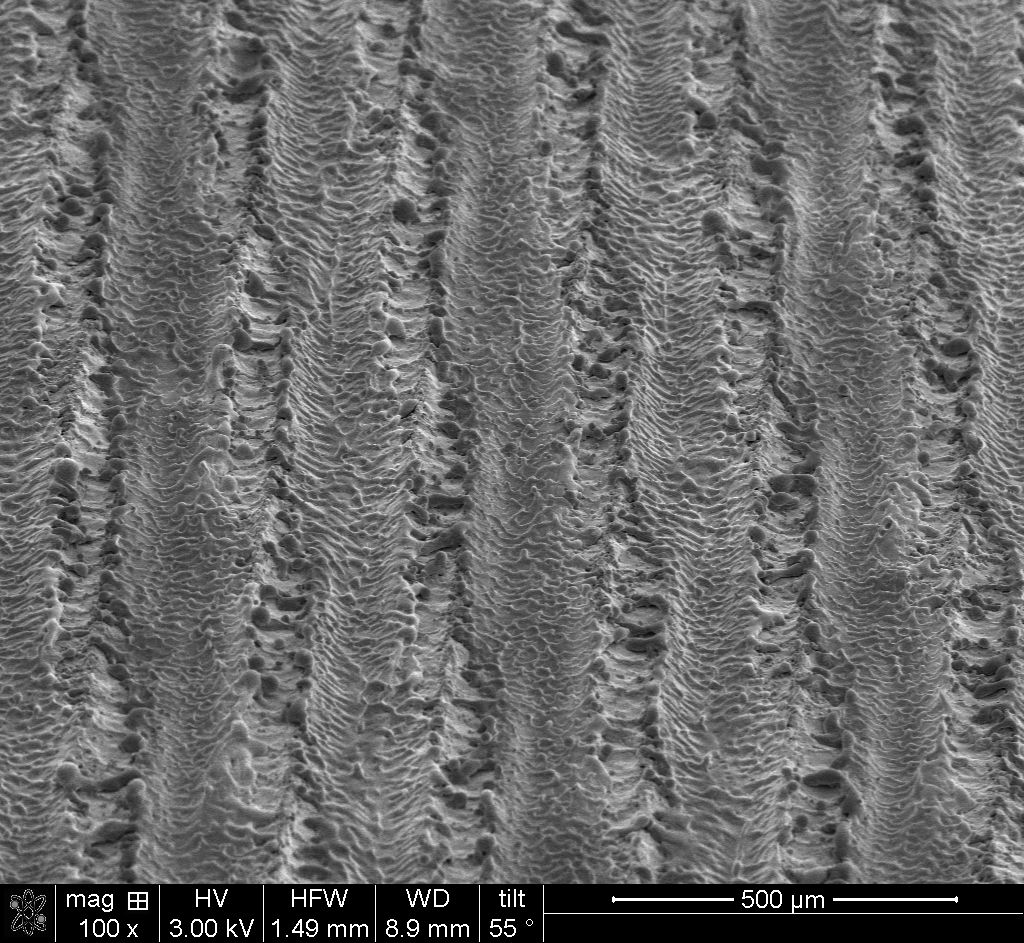

Laser texturing can be used to create different patterns on metal surfaces to affect, for example, adhesion properties. Line patterns and hole patterns are common texturing types. The following SEM (scanning electron microscope) images show what a textured surface looks like.

Line Pattern (Grooves)

Hole Pattern (Dimples)