How Does Rust Removal Work?

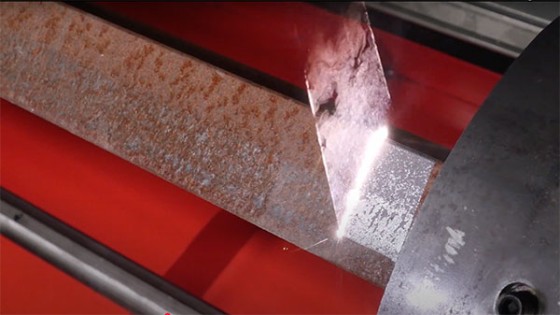

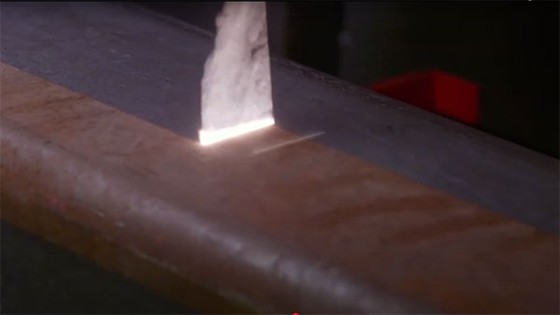

Every material has an ablation threshold, the point at which it begins to break down under laser energy. Rust has a lower threshold than most metals, which makes laser cleaning a great solution. You can set precise parameters so the beam’s intensity is strong enough to vaporize the rust while staying below the ablation threshold of the base metal.

As the beam scans the part, laser energy converts layers or rust into vapour and dust, leaving behind a clean, unaltered surface. Because you can set laser cleaning systems to precise parameters, it makes laser rust removal adaptable for fine, high-precision parts or large, heavily oxidized surfaces.

Our high-power systems can clean light rust at rates up to 50 cm² per second, while heavily corroded surfaces are cleaned at about 5 cm² per second. You’ll get the best results by fine-tuning your parameters and testing the results. We can run tests on your parts to help you find the best solutions.

Two Types of Lasers for Rust Removal

The type of laser you’ll need depends on the level of precision required and your specific application.

Single-Mode Lasers

Single-mode fiber lasers produce a narrow, focused beam, making them ideal for precise rust removal. You can clean specific areas or texture surfaces before painting, applying adhesives, or welding. The tight beam control ensures consistent results without affecting surrounding areas.

Multi-Mode Lasers

Multi-mode fiber lasers can create a wider beam that covers more surface area. They’re best for speed and efficiency, quickly vaporizing rust while leaving the base metal untouched.

Why Traditional Rust Removal Methods Fall Short

Conventional rust removal techniques often create more problems than they solve. Here’s how lasers compare:

Shot-Blasting and Sand-Blasting

Blasting is abrasive. While it strips rust, it also tends to erode the base metal. Rust also mixes with the media, leaving a less clean surface, and parts can distort or lose tolerance. On the other hand, lasers remove rust precisely without damaging the substrate.

Dry-Ice Blasting

Dry-ice blasting is non-abrasive, but it lacks precision and struggles with small or complex geometries. It also generates CO₂. By comparison, lasers provide clean, targeted removal without environmental drawbacks.

Chemical Methods Involving Acids

Chemical treatments dissolve rust but lack the control you need, often stripping more than you intended. They also require handling hazardous materials and waste. Laser cleaning is a dry, chemical-free, and more consistent process.

Limitations of Laser Rust Removal

While highly effective, laser rust removal does have some limitations:

- Complex surface geometry: Intricate or recessed shapes may require special setups.

- Large surfaces: Cleaning very large areas can be slower than blasting methods.

- High-mix production: Switching frequently between varied part types can make automation more complex.

Laser Rust Removal Applications

Laser cleaning is flexible enough to handle both small components and heavy equipment. Here are a few specific examples:

- Steel pipes in automotive: Restoring surface appearance before shipping.

- Aerospace ingots up to 500 lbs: Removing rust without reducing valuable base material.

- Heavy-duty drivetrain components: Refurbishing large vehicle parts instead of replacing them.

- Internal cavities of lug nuts: Clean hard-to-reach areas with conveyor-based laser systems.

- Casted metals in volume: Removing rust and applying passivation on parts like brake discs to prevent reoxidation.

Industries Using Laser Rust Removal

Laser rust removal is widely used across industries where precision, safety, and efficiency are critical, such as:

- Automotive: Cleaning of parts like brake discs, pipes, and drivetrain components.

- Aerospace: Quality validation and preservation of valuable components sold by weight.

- Medical: Precision cleaning of surgical tools and medical devices for compliance and performance.

- Manufacturing: Streamlined automation, elimination of masking, and reduced environmental impact.