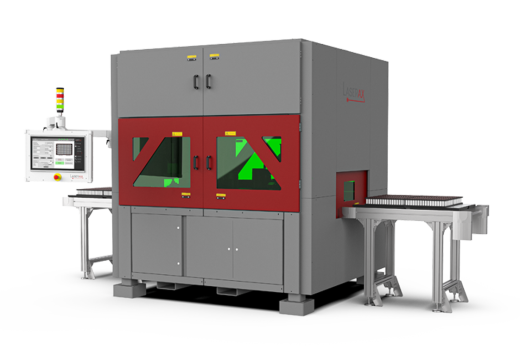

Battery Laser Cleaning Workstation

The Battery Cleaning Workstation is the perfect solution for low-volume production lines or to start a new one quickly. Available for purchase or rental, it provides a smooth transition to a fully automated solution that can keep up with high production rates.

Read more