Sand Marking Applications

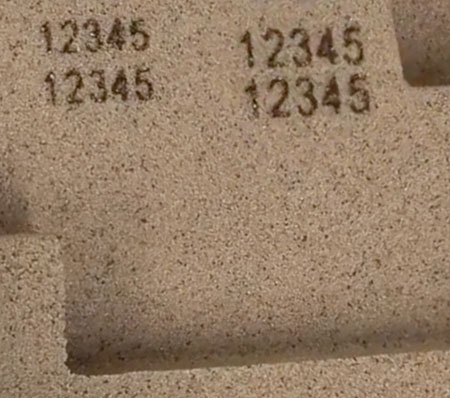

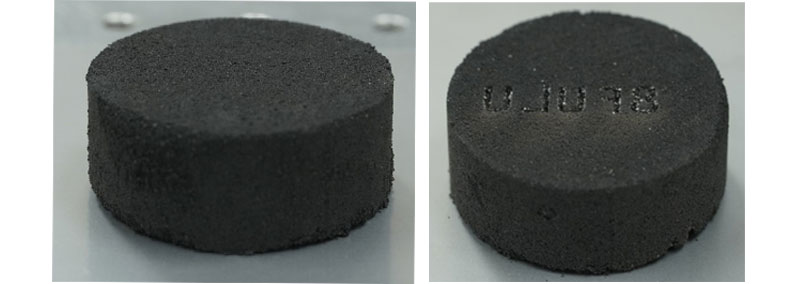

Laser marking can be used to engrave serial numbers, text, and logos on sand molds used for metal casting. This process is known as sand marking. After the casting process, identifiers “stick out” the part so they can be read using barcode readers. The characters’ shape and depth are controlled by the marking process, but they are also affected by the quality and consistency of the casting process.

Laser marking can be used to engrave serial numbers, text, and logos on sand molds used for metal casting. This process is known as sand marking. After the casting process, identifiers “stick out” the part so they can be read using barcode readers. The characters’ shape and depth are controlled by the marking process, but they are also affected by the quality and consistency of the casting process.

Sand marking is a great alternative to inserts and mechanical engravings. It allows for unique markings on each sand casted part without the need for inserts or modifications to the mold’s design each time. The process is highly precise and can be fully or semi-automated.

| Benefits | Applications |

|---|---|

|

|

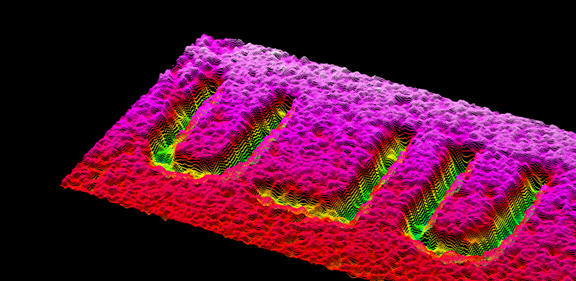

Sand Marking Depth

Laser marking depth is affected by factors such as:

- The number of laser passes

- Sand compression

- The type of sand

- The grain size

- Glue additives

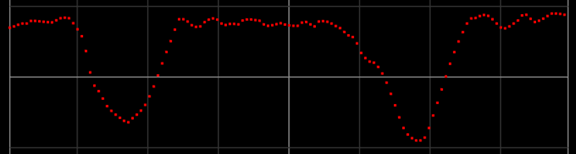

Sand Marking Speed

Sand marking is a fast marking process. Since sand molds are brittle, their grains are easily removed by the laser beam. Faster markings speeds can be obtained by modifying the system’s parameters.

To obtain sand marking speeds, Laserax used the character “8”—the worst-case scenario in terms of complexity. This allows us to guarantee high-quality markings for the given speeds

Laser marking speed is affected by factors such as:

- The type of sand and its condition

- The size, depth, and thickness of the characters

- The laser power

| Depth (mm) | ||||

|---|---|---|---|---|

| Height (mm) | 0.70 - 0.90 | 1.40 - 1.80 | 2.10 - 2.70 | 2.80 - 3.60 |

| 4 | 0.15 s | 0.25 s | 0.35 s | 0.45 s |

| 8 | 0.25 s | 0.45 s | 0.70 s | 0.90 s |

| 12 | 0.40 s | 0.75 s | 1.10 s | 1.45 s |

| 16 | 0.55 s | 1.05 s | 1.55 s | 2.05 s |

* The character “8” was engraved in green sand using a Laserax 200W pulsed fiber laser

When marking sand, 100W or 200W lasers are the most suitable solutions. If more is speed is needed, multiple 100W or 200W lasers will perform better than a single higher-power laser of equivalent power.

| Depth (mm) | ||||

|---|---|---|---|---|

| Laser Power (W) | 0.70 - 0.90 | 1.40 - 1.80 | 2.10 - 2.70 | 2.80 - 3.60 |

| 100 | 0.45 s | 0.85 s | 1.25 s | 1.68 s |

| 200 | 0.40 s | 0.75 s | 1.10 s | 1.45 s |

| 300 | 0.40 s | 0.70 s | 1.05 s | 1.40 s |

| 500 | 0.35 s | 0.70 s | 1.00 s | 1.35 s |

* The character “8” was engraved 12 mm high in green sand using a Laserax pulsed fiber laser