Automotive Traceability

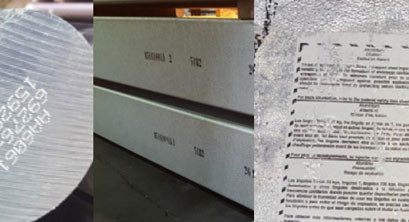

Laser marking is used to permanently identify various automotive parts such as drivetrains, engine components, EV batteries, brakes, suspension components, seat structures, and stampings.

Laser marking is the process of permanently marking a surface using a focused beam of light. It can be performed using different types of lasers, including fiber lasers, CO2 lasers, pulsed lasers, and continuous lasers. The three most common laser marking applications are:

Laser marking can mark a variety of materials such as steel, aluminum, stainless steel, polymers, and rubber. It is often used to identify parts and products with 2D barcodes (data matrix codes or QR codes), alphanumerical serial numbers, VIN numbers, and logos.

To create a lasting mark, laser marking systems generate focused beams of light that contain high levels of energy. When a laser beam hits a surface, its energy is transferred in the form of heat, creating black, white, and sometimes colored marks.

Laser beams are generated by a reaction known as LASER, an acronym for “Light Amplification by the Stimulated Emission of Radiation”.

First, a special material is stimulated with energy, making it release photons. The newly released photons then stimulate the material again, generating more and more photons. This creates an exponential number of photons (or light energy) in the laser cavity.

This energy build up is released as a single, coherent beam of light that is directed at its target using mirrors. Based on the energy level, it can etch, engrave, or anneal surfaces with extreme precision.

Laser light energy is measured using wavelengths, or nanometers (nm). Specific wavelengths are used for different applications and can only be generated by certain types of lasers.

Laser marking has become the technology of choice for manufacturers looking for high-quality marking, offering a multitude of advantages compared to older marking methods like dot peen marking, inkjet printing, and printed labels.

Laser marking is the fastest direct part marking technology, making it a sought-after option when short cycle times must be met. Laserax takes pride in benchmarking the fastest lasers on the market due to the high-quality of our hardware and software components.

Laser marking is a precise process that provides consistent results. You get a near perfect readability rate, making sure that the number of nonconform parts is kept to a minimum.

Laser marking makes the manufacturing world more sustainable by replacing polluting technologies that rely heavily on consumables. Fiber laser technology is also known for its electrical efficiency, further reducing your environmental footprint.

Laser marking is a non-contact process, so no mechanical wear occurs between the system and the part being marked. This helps you keep maintenance and downtime to a minimum. Minimal maintenance is needed to remove the accumulated dust from the lens.

Laserax offers solutions that include everything needed to implement laser marking in production lines. We offer manually loaded and automated solutions with 100% laser safety, dust and fume management, barcode validation, and remote support.

Laser marking is used to permanently identify various automotive parts such as drivetrains, engine components, EV batteries, brakes, suspension components, seat structures, and stampings.

Laserax has developed optimized laser marking processes for metals. They are used in plants all over the world to mark all types of metals, including aluminum, steel, stainless steel, magnesium, led, and zinc.

Laserax has developed unique processes to etch or engrave identifiers that maintain traceability through post treatments like shotblasting, heat treating, powder coating, and e-coating.

Each marking method has its benefits and drawbacks. Between dot peening, inkjet printing, and laser marking technology, you need to choose the method that best fits your needs.

To find the right laser marking system, you need to have a few pieces of information that will set you in the right direction. You can then choose the type of laser, the laser power, and the laser machine that you need.

Fiber laser markers are at the core of our solutions. In this piece, we answer several questions. When was the fiber laser invented? What are the types of fiber lasers? How long do they last? What are their components and parameters?

Knowing the difference between the main types of lasers is useful when choosing a system for your marking application, especially if you don’t know whether you need a fiber laser, a CO2 laser, or an ND:YAG laser, and whether a pulsed or continuous laser is appropriate.

Receive monthly updates and latest news.

© 2026 Laserax ®. All Rights Reserved.