Industrial Laser Solutions For The Automotive & EV Industry

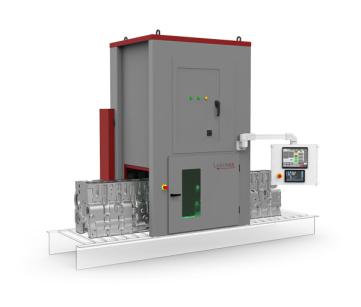

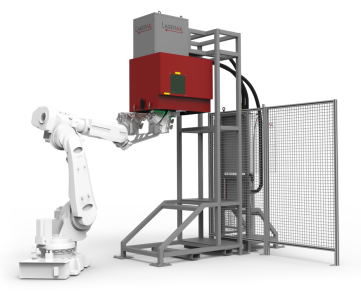

To address the most demanding automotive requirements, Laserax provides the fastest lasers on the market. Our turnkey solutions are built with industrial grade components and meet class-1 laser safety standards.

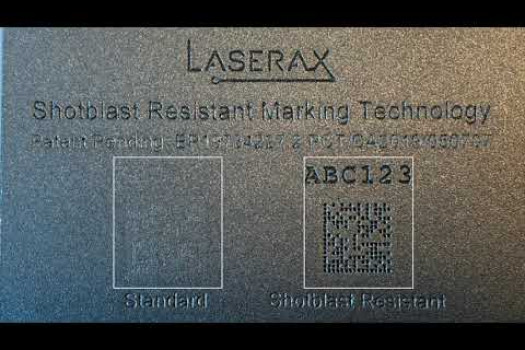

We’ve developed exclusive processes for the industry. Our laser marking meets cradle-to-grave traceability requirements when parts are shotblasted, coated, and so on. Our cleaning expertise also allows manufacturers to get rid of masking. They can selectively remove paint instead, leaving a texture that improves adhesion if needed.

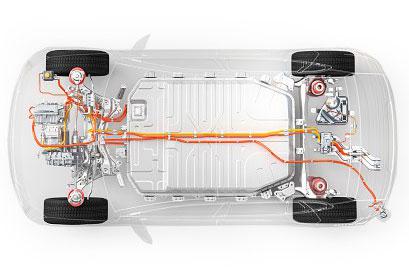

With the current transition from combustion engines to electric motors, lasers will play an even bigger role than before, with laser cleaning and welding becoming major processes for battery manufacturing.