Laser Marking & Cleaning Drivetrains

Fiber lasers provide important advantages for the identification of ring gears and pinions. They can etch 2D codes that maintain traceability through phosphate coating and heat treatments.

To ensure a strong assembly, the same laser can also selectively remove phosphating from certain areas without affecting the metal underneath.

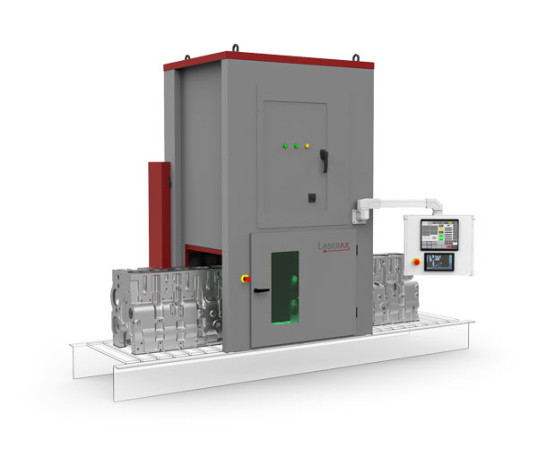

Laserax offers complete laser solutions that include vision, validation, dust extraction, and a lot more.