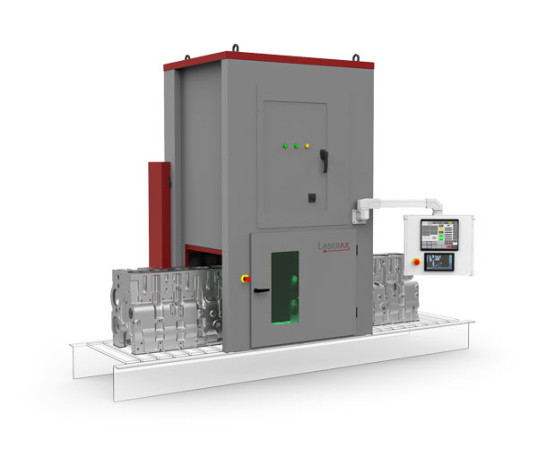

Brake Manufacturing With Laser Technology

By replacing technologies like sandblasting, chemical baths, and dot peen systems, laser technology allows you to get rid of numerous consumables, minimize recurring costs, and improve quality—all of this without affecting cycle time.

Fiber lasers can remove oxides and coatings from brake pads, texture surfaces to improve adhesion, and create robust, high-contrast identifiers for unmatched traceability. All these processes can be performed with a single unit.