How to Remove Aluminum Oxidation - 4 Methods Explained

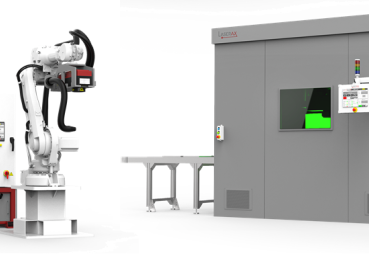

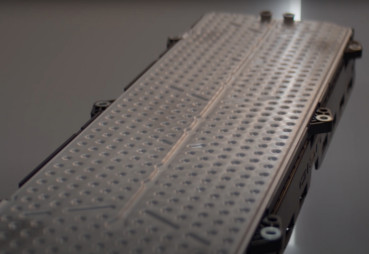

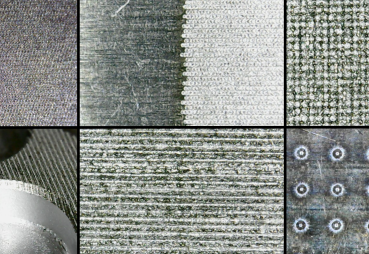

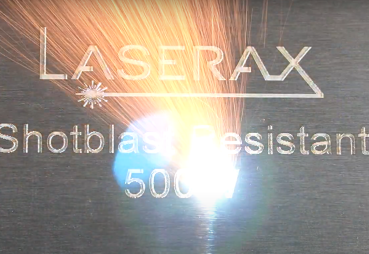

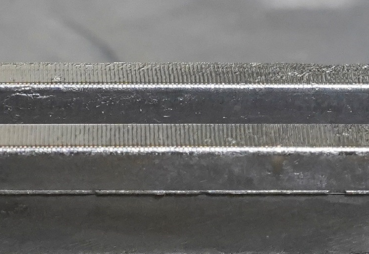

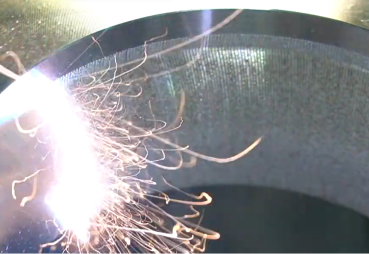

Oxide removal is essential to prevent weld contamination, maximize the bond strength of coatings and adhesives, and increase part durability. Laser cleaning, mechanical abrasives, pickling chemicals and other chemicals have all proven effective in cleaning oxidized aluminum.