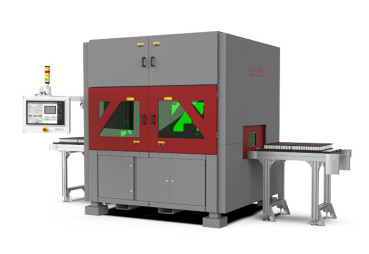

Automated Laser Welding: Components, Benefits & Applications

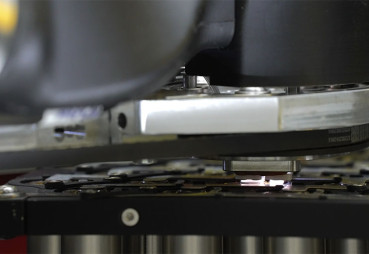

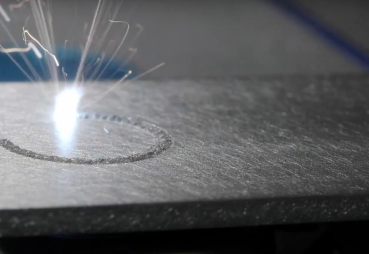

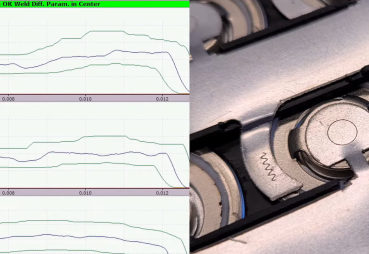

Automated laser welding is a cutting-edge manufacturing process that merges the precision of laser technology with the consistency and speed of automation. At its core, it’s the use of a laser beam (typically guided by a scanning optic, robotic, or gantry systems) to fuse materials in a controlled, noncontact manner.