Laser System Options

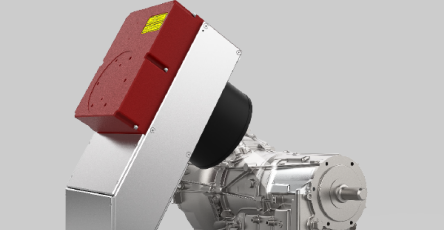

Laser Power

The LXQ-UHP offers between 500W and 3kW of laser power for the most demanding cleaning applications.

Depth of Focus

The LXQ-UHP sets a high standard with a depth of focus of up to 20 mm. You get the freedom to process any types of geometries, compensate for bended parts, and prevent complex laser head adjustments.

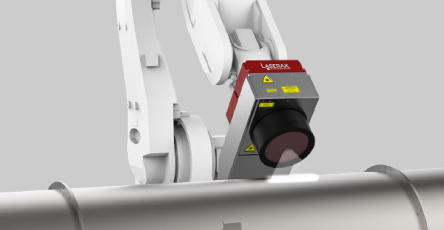

Fiber Cable Length

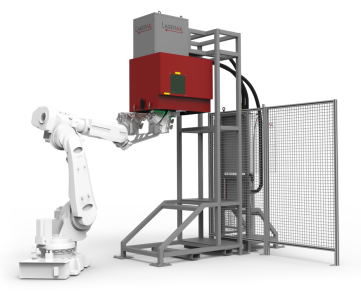

Offering between 10m and 100m of fiber cable length, our laser heads can process large areas as needed. They can easily be mounted on robots, gantry systems, and the like.

Optical Configuration

The standard optical configuration is optimal for most cleaning applications. Not only does it offer a huge working field, but the lens is at a good distance from the part to prevent the dust generated by the laser cleaning from accumulating on the lens.

Advanced optical configurations are used for applications with atypical requirements. Some coatings, for example, need to be cleaned with a higher energy density than usual. Optical elements can be combined in a way that maximizes energy delivery for this specific process.

Standard Accessories

The air-knife is installed on the lens, blowing a continuous airstream that protects it against dust accumulation. The lens needs to be cleaned less often and you obtain results that are much more consistent.

Our optional Class-1 enclosures offer you a quick way to guarantee laser safety.

The HMI control panel provides direct access to laser marking parameters. You can:

- Manually adjust the laser marking zone

- Enter the manual operation mode to run tests or calibrate the laser

- Display information such as the system status, the operation mode and the alarm history

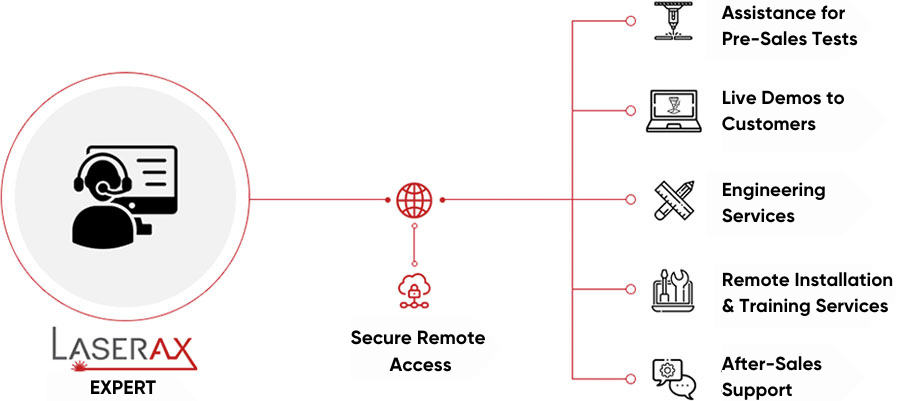

For our complete list of features and options, contact a Laserax expert.