Laser System Options

Laser Power

Fiber laser markers range from 20W to 100W depending on the marking speed required for your application. Higher laser powers that range from 200W to 500W are also offered as part of the LXQ-HP series.

Laser Head

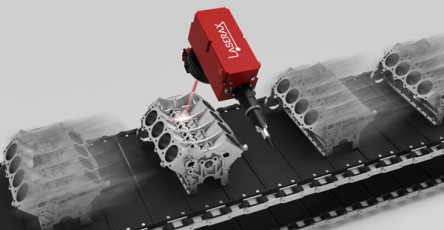

We offer two types of laser heads. 2D heads are used to mark flat surfaces and can easily compensate for surface roughness imprecisions. 3D heads can be used to mark any types of geometries, compensate for bended parts, and mark at a 45° angle.

Optionally, 3D heads can be used with our 3D-Autofocus for an even greater part-positioning tolerance. All laser heads are completely sealed off, protecting them from dust, water, oil particles and other contaminants.

Lens Configuration

Our standard lens configuration provides the best optical configuration for most part marking requirements, offering an industry-leading marking field and marking distance that helps reduce dust generated by laser marking from accumulating on the lens.

Our advanced lens configuration is used to engrave the most durable markings such as the ones that maintain traceability after shotblasting.

Standard Accessories

The air-knife prevents dust accumulation on the lens by blowing a continuous airstream. This reduces lens cleaning maintenance and guarantees a consistent marking quality.

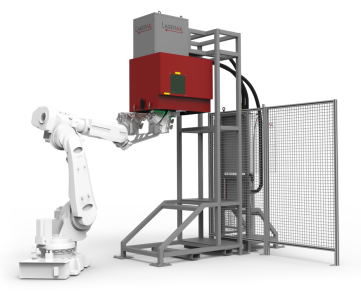

Our Class-1 open-air enclosures can be integrated in your solutions, allowing you to quickly obtain your laser safety certification.

Advanced Features

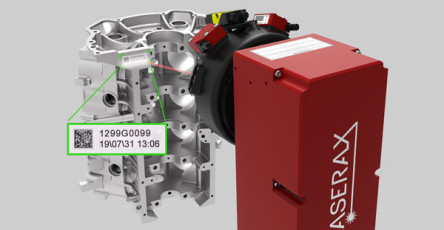

Our 3D Autofocus automatically detects part-positioning variations and adjusts the marking configuration to consistently generate high-contrast markings. This feature prevents complex laser head adjustments.

Our barcode validation feature monitors marking quality right after 2D codes are marked. Our validation system and Cognex camera can predict which 2D codes will live up to the marking benchmark, even if the parts undergo post surface treatments.

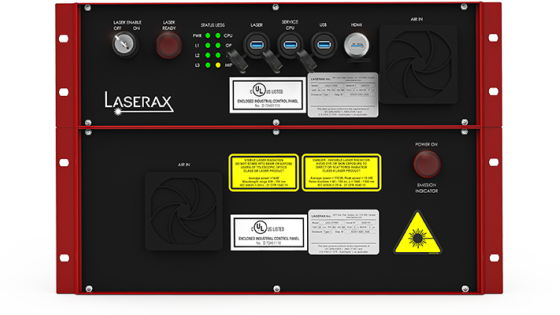

These advanced features can easily be integrated by directly connecting peripherals on the controller’s back panel.