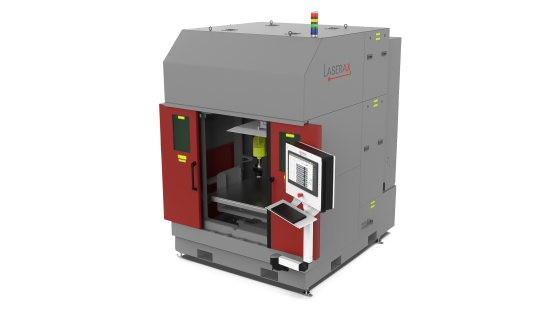

VERSA Laser Welding Machine

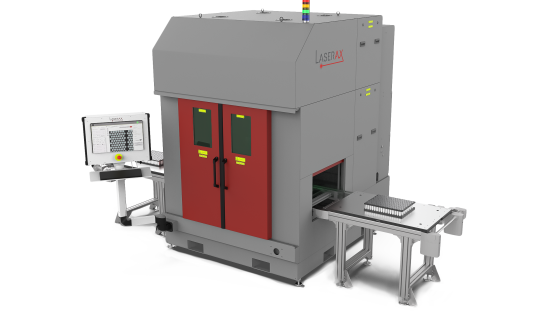

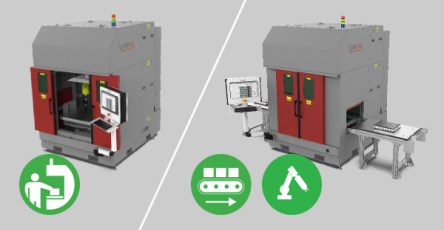

The Versa Laser Welding Machine is purpose-built for R&D, prototyping, and medium-to-low volume battery production. Its name reflects the versatility it brings to battery manufacturing, suitable for prismatic, cylindrical, and pouch cells, with configurations ranging from manual to fully automated loading.

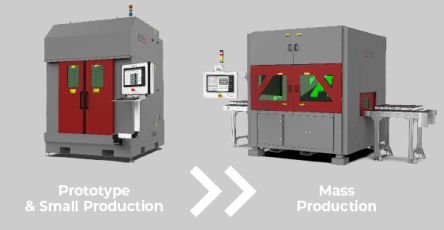

This battery laser welding machine is designed as a modular solution, giving you the flexibility to add advanced features as needed, such as dynamic clamping, integrated vision, and AI-powered weld quality monitoring. It is powered by the same core technology as our high-volume machine, allowing for a future-proof investment with seamless transferability to mass production.