Laser Machine Options

Laser Power

The Open Air machine can be equipped with fiber lasers that range from 20W to 500W to meet all types of marking speed requirements.

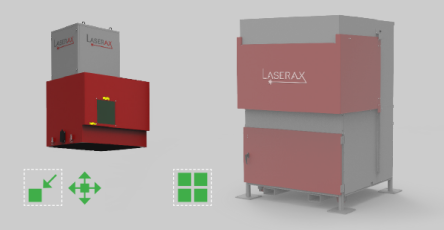

X-Y Vision System

The vision system helps the robot position parts in front of the laser marker, reducing or eliminating X and Y positioning errors. You need it if part positioning variations are too high for the marking process.

HMI Control Panel

The standard HMI control panel provides direct access to laser marking parameters near the machine. You can:

- Manually adjust the laser marking zone, scale the identifiers, edit them and more

- Enter the manual operation mode to run tests or calibrate the laser

- Display information such as the system status, the operation mode and the alarm history

If you want to add custom features in the HMI, contact us.

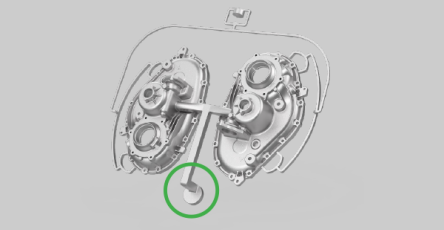

Barcode Validation

Marking quality can be verified directly in the machine with our standard barcode validation system and precalibrated Cognex camera.

VisionView

To comply with the latest industrial traceability standards, Cognex’s VisionView can be integrated directly in our standard HMI to help you visualize reading results as well as perform maintenance and diagnostics on the barcode reader. You gain access to their standard views and database analysis tools, which can be used for production lot tracking, marking quality statistics and much more.

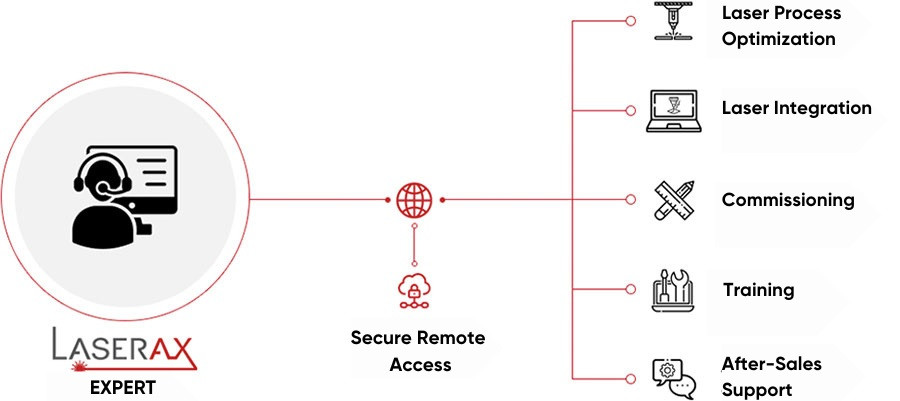

For more machine options, contact a Laserax expert.