Linear UV Laser Marking System

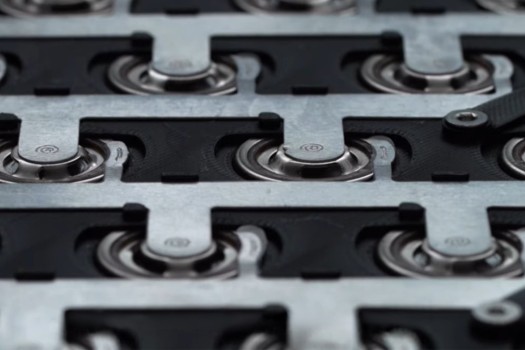

The Linear UV Laser System offers high precision and speed for coding/marking, micro-machining, texturing and drilling applications. Its versatility and marking-on-the-fly capability enable high-volume, permanent markings on plastics, glass, metals, ceramics, and PCBs, making it perfect for traceability and identification on sensitive materials.

Read more