Automotive Part Marking Technologies - Which One to Choose?

If you are struggling to find a marking method for traceability, or simply for process improvement, you are not the only one.

Laser Direct Part Marking (LDPM) is the identification of individual parts (or bundle of parts) with unique identifiers. The identifiers are marked directly onto the products. Download the guide: Industrial Traceability - How Barcodes Work to learn more on the best 2D codes for industrial applications.

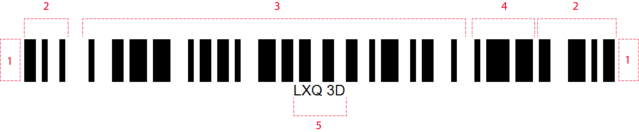

The most common linear barcode is code 128. It features a procedure for encoding the entire ASCII 128 character set. The encoding of a code 128 barcode includes 3 symbols at the beginning and 2 at the end (2). It can hold 103 symbols for carrying the message (3). One of the most interesting features of Code 128 is its validation characters (4). It permits to verify that the scanner has correctly read the message. Finally, a quiet zone (or empty space) has to be kept empty before and after the barcode (1).

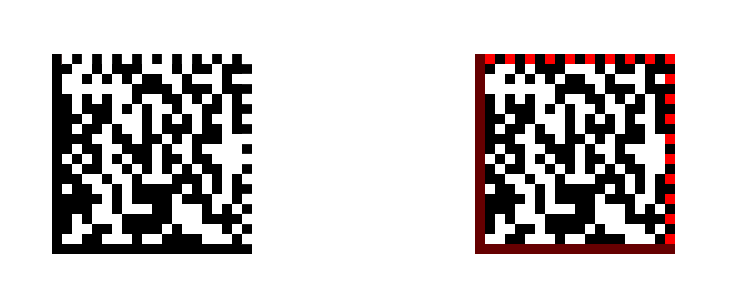

Data Matrix Codes are composed of a full line on two of its sides and alternating black and white pixels on the two other sides. This line provides sufficient information to locate the code and give the necessary information on the number of pixels the code has vertically and horizontally (because DMCs can also be arranged in a rectangular shape). Within these borders, we find black and white pixels in, what seems to be, random pattern. For bigger DMCs, you might also find solid black lines separating the code in equal sectors.

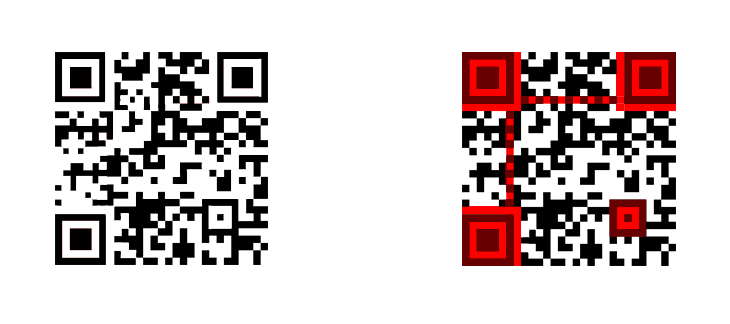

Quick Response Codes require more localization features. They are formed of four squares in the shape of a target. You can also recognize the same seemingly random arrangement of black and white pixels as for DMCs.

Thanks to the Reed-Solomon algorithm, the error correction of Data Matrix Codes and QR Codes provides a high redundancy. DMCs and QR Codes can both be legible even when up to 30% of the code is destroyed. The difference is that the error correction level is automatically determined by the remaining storage capacity for DMCs, whereas the error correction level can be selected manually for QR codes (the highest level is H for 30%).

For a comparable code size, the storage capacity of DMCs is much better than that of QR codes. See the table below for a quick comparison.

DMC ECC 200 30% correction level | QR Code Level H (30%) | ||||

|---|---|---|---|---|---|

| Dimension | Capacity | Dimension | Capacity | ||

| (# of pixels) | Numeric | Alphanumeric | (# of pixels) | Numeric | Alphanumeric |

| 10 | 6 | 3 | N/A | ||

| 14 | 16 | 10 | N/A | ||

| 20 | 44 | 31 | 21 | 17 | 10 |

| 22 | 60 | 43 | |||

| 40 | 228 | 169 | 41 | 139 | 84 |

| 80 | 912 | 682 | 81 | 602 | 365 |

| 120 | 2100 | 1573 | 121 | 1425 | 864 |

| 144 | 3116 | 2335 | 145 | 1897 | 1150 |

| N/A | 165 | 2625 | 1591 | ||

| N/A | 177 | 3057 | 1852 | ||

GS1 is an organization that develops standards ensuring the most reliable and legible codes possible. The main characteristics tested by GS1 are the code's contrast, modulation, quiet zone and readability. Barcodes, QR codes and Data Matrix Codes that comply with GS1 standards are sure to provide the best possible legibility.

Regular barcodes are simple and include limited information. They usually have a way to confirm the accuracy of scans but they have no built-in redundancy. A badly placed scratch will render the information indecipherable. Linear barcodes are not the best solution for industrial applications, such as laser direct part marking.

2D codes have a much higher density of information. Redundancy ensures that even if portions of the code are erased, it is still possible to gain access to the full information. The two most common 2D codes are Data Matrix Codes and QR codes. Data Matrix Codes are advantageous for industrial applications because they have much more storage capacity for the same surface area and for the same error correction level.

* GS1 DataMatrix Guideline: Overview and technical introduction to the use of GS1 DataMatrix . rel 2.5.1 , GS1, January 2018. Retrieved from https://www.gs1.org/docs/barcodes/GS1_DataMatrix_Guideline.pdf

**GS1 General Specifications: The foundational GS1 standard that defines how identification keys, data attributes and barcodes must be used in business applications. rel 17.1 , GS1, July 2017. Retrieved from https://www.gs1.org/sites/default/files/docs/barcodes/GS1_General_Specifications.pdf