Permanent Part Marking Methods Guide for 2025

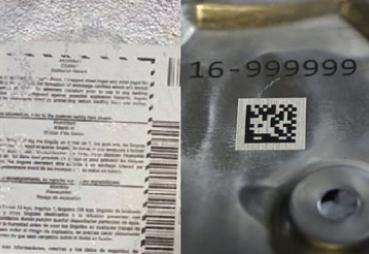

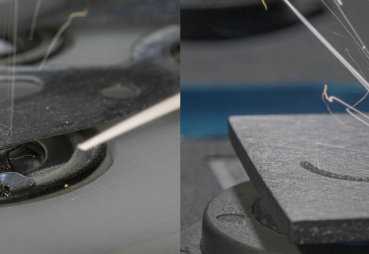

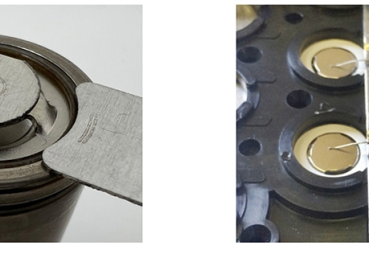

Permanent part marking ranges from logos and serial numbers to barcodes and certification marks. It’s a critical step in manufacturing as a way to maintain control over quality, comply with regulatory requirements, and ensure the traceability of products.