Laserax Acquires Leading UV Laser Manufacturer DPSS Lasers Inc.

Laserax, a global leader in advanced laser solutions, has acquired DPSS Lasers Inc., a California-based leading manufacturer of high-power, 355 nm Ultraviolet (UV), solid-state lasers.

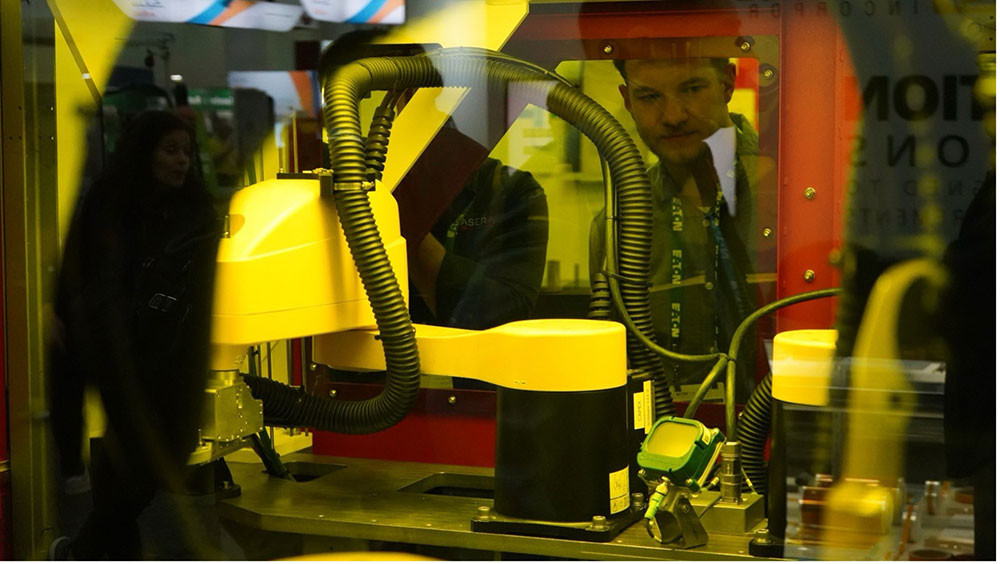

The Battery Show USA 2024 showcased the latest innovations in battery technology, bringing together industry leaders, experts, and enthusiasts to discuss advancements in EV and energy storage. Laserax was thrilled to participate, presenting our cutting-edge laser solutions to help manufacturers achieve efficient, high-quality battery production. Our goal was to not only highlight our innovations but also to engage with industry professionals, understand their challenges, and align with their needs.

Here are our 6 takeaways from this year's edition:

If there’s one takeaway that stood out, it’s that laser technology is now considered the standard for battery manufacturing. Unlike slower mechanical methods like wire bonding, lasers offer the precision and speed needed for modern production demands. Its versatility allows for multiple applications, such as battery welding or cleaning. This shift reflects a broader trend toward efficiency and scalability, which are critical as the market grows.

One couldn’t miss the emphasis on large-scale production at this year’s show. Unlike previous years, when companies concentrated on R&D and prototyping, the focus in 2024 has shifted more toward scaling up. Major players are moving from the drawing board to the production floor, adopting automation to enable mass production. Laserax’s technology supports these goals with scalable, high-efficiency solutions adaptable to various battery types and production setups.

Our product showcase event and live demos turned a lot of heads. Watching the technology in action was a highlight for many attendees who wanted to see how these machines could fit into their own operations, visitors were keen to understand how our solutions could address their challenges.

The Adhesive industry had a strong showing at the Battery Show, underscoring its crucial role in battery assembly. We’ve been working with Adhesive companies to explore how laser texturing could help enhance bonding performance by optimizing surface properties. With their collaboration, we’ve been able to demonstrate laser texturing ability to elevate these processes, allowing adhesives to perform better and creating more durable and reliable bonds in battery assembly.

For many companies, especially those in early development stages, finding a reliable partner is essential. Attendees highlighted the importance of collaboration, looking for partners who could help them navigate the complexities of prototyping, production, and scale-up. With dedicated labs and expertise in laser process development, we strive to offer resources and guidance that support manufacturers in reaching their goals. Our paper on the Challenges of Laser Welding Batteries resonated strongly, addressing issues many visitors face in the industry.

The automotive sector, a major battery consumer, has slowed this year, while battery storage has gained momentum. Numerous companies are scaling production, with substantial growth anticipated as EV and green energy adoption rise. Industry insiders remain optimistic, expecting a strong rebound once political and economic uncertainties clear.

The Battery Show USA 2024 was an eye-opening experience, highlighting the rapid progress and future potential of battery manufacturing. If you're interested in learning more, have a look at our page about laser cleaning and marking of EV battery modules or our page about battery laser welding.

François Lamy is a Marketing Content Specialist at Laserax, committed to crafting valuable content that educates the industry on the transformative role of laser technology in manufacturing. His work empowers manufacturers with insights into the latest advancements and applications of laser solutions.