Laser System Options

Laser Power

Our UV laser markers range from 1W to 55W. Power options currently available are: 1W, 2W, 3W, 5W, 10W, 15W, 20W, 40W and 55W.

Laser Pulse Duration

Our UV laser markers are available in nanosecond (ns), picosecond (ps), and femtosecond (fs) pulse durations to match the laser process to the material's absorption characteristics and application requirements.

Picosecond and femtosecond UV configurations are offered in specialized setups, as they require a format different from the standard-size Linear Head.

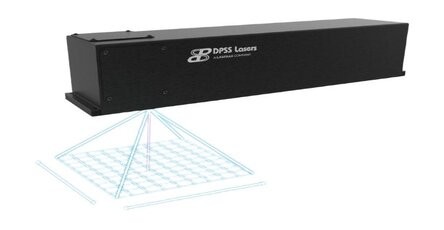

Spot Size

Our wide spot size range (7-100um) makes it easy to tailor the laser solution to your specific applications, materials and power/speed requirements.

F-Theta Lens

If the spot and field sizes are compatible, an f-Theta lens can keep the laser beam in sharp focus. It also ensures consistent 2D marking on flat surfaces.

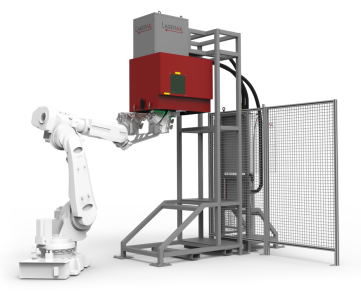

Marking On the fly (MOTF)

Marking-on-the-fly (MOTF) capability enables high-speed marking on moving parts, using real-time encoder feedback to dynamically adjust laser firing timing.

This is critical for inline production lines where stopping parts is not feasible. The system compensates for linear speed variations, ensuring precise and distortion-free marks.

Quadrature Signal

Quadrature encoder input (A/B channels with optional Z-reference) enables high-resolution positional feedback for synchronized laser marking.

This signal allows the laser controller to accurately calculate velocity and displacement in real time, ensuring precise trigger points and consistent mark positioning—especially important in rotary or conveyor-based systems.

Communication Protocol

The UV laser system supports industrial-grade communication protocols such as EtherNet/IP, PROFINET, Modbus TCP, and RS-232/485.

This flexibility enables direct integration with PLCs, HMIs, and SCADA systems for real-time control, diagnostics, and traceability.

It simplifies system architecture and enhances interoperability in Industry 4.0-ready environments.

Fume Extraction

Laser marking of plastics and other materials can generate hazardous fumes and fine particulate matter. Our fume extraction units integrate HEPA and activated carbon filtration, removing harmful emissions and protecting both optical components and personnel.

Power Meter

An external power meter module enables real-time monitoring of UV laser output at the work surface, measuring actual delivered energy to ensure process stability.

It helps calibrate marking parameters and detect power drift in precision-critical environments. This is especially valuable in production settings requiring consistent laser fluence across batches.