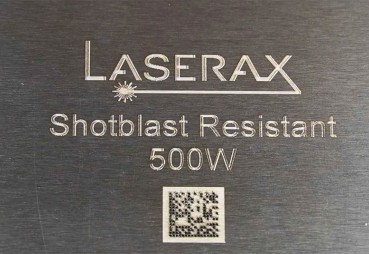

Wafer Marking: Laser Solutions for Semiconductor Identification

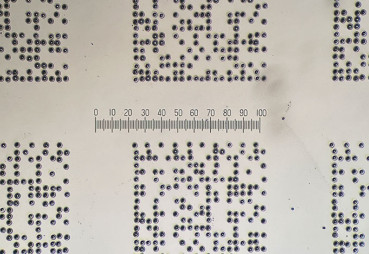

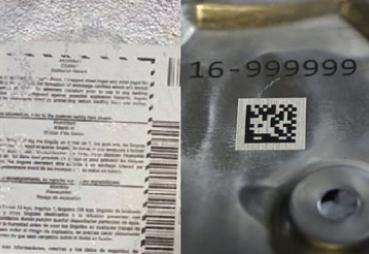

Semiconductor manufacturing requires incredible precision. In an industry where one micron is considered large, even minor process deviations can compromise yield or performance. Laser wafer marking is often the best solution, offering non-contact processing with high repeatability and integration into automated workflows.