Superior Metal Bonding with Laser Surface Preparation

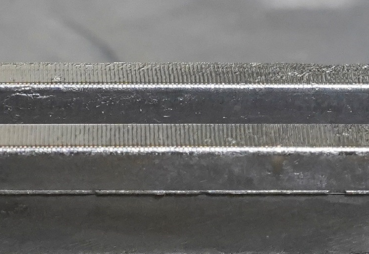

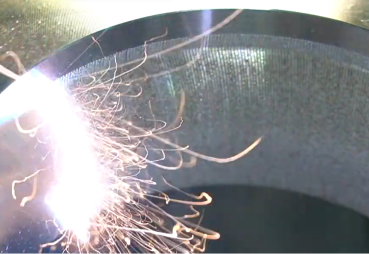

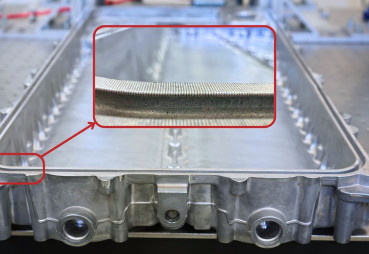

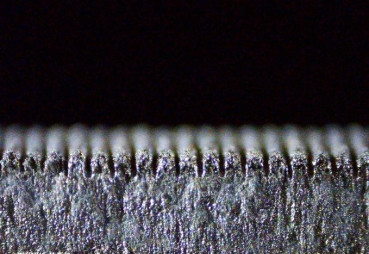

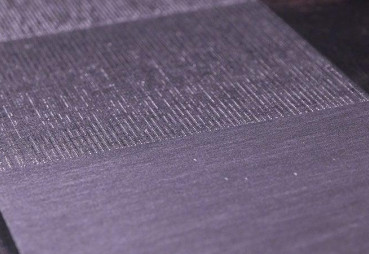

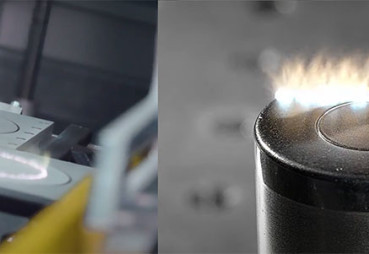

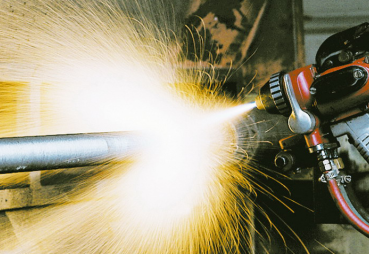

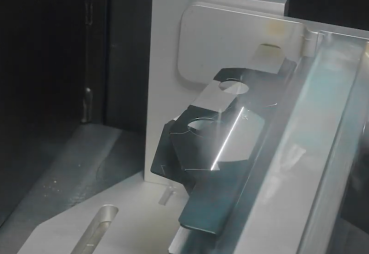

Grit blasting and chemical etching are typically used to prepare metals for bonding. However, lasers offer a new, alternative approach that leads to superior bonding quality, increased efficiency, and lower operational costs