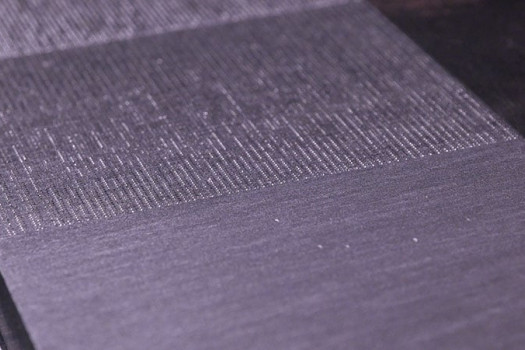

Laser Texturing Performance for Metal Surfaces

This technical paper reports the texturing speeds obtained at different power levels for typical levels of surface roughness required for metals like steel and aluminum.

Read more

This technical paper reports the texturing speeds obtained at different power levels for typical levels of surface roughness required for metals like steel and aluminum.

Read more

In Inovaweld’s production line, more than 40,000 stainless steel barrels can be manufactured in a single year. As part of their manufacturing process, they must clean stainless steel to remove oxides from welding joints (including butt joints and lap joints). Once stainless steel is cleaned, they must make sure that it is passivated to protect it from corrosion.

Read more

This technical paper offers detailed information on the marking performance of Laserax laser systems for the aluminum industry.

It provides laser marking times at different power levels and focus tolerance values with 2D and 3D laser marking systems.

Read more

This technical paper reports the cleaning speeds obtained for typical industrial contaminants, namely rust, paint, dust, oil, and mill scale.

Read more

Paint Removal off a Wheel with Laser Cleaning

Read more

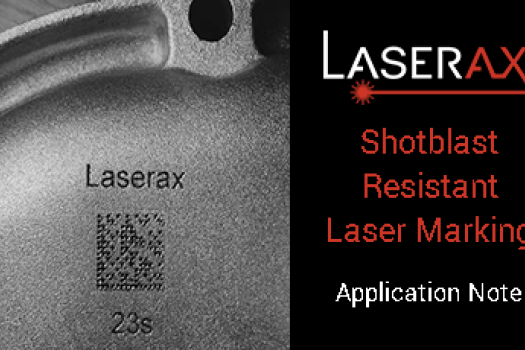

This white paper gives an extensive look into the development of Laserax's patent-pending shotblast resistant laser marking. For a quick overview read the application note.

Read more

Laserax has developed an exclusive patent-pending laser direct part marking process designed to withstand shotblasting. Get an overview of the process in this application note.

Read more

Laser marking is a very promising solution to the challenges of traceability faced by many plant managers. Laserax modular laser systems are easy to integrate in automated production lines or autonomous production cells. Download Laser Marking Guide for Plant Managers and Other Non-tech Types

Read more

Laser direct part marking (DPM) can be used on various non-ferrous metals to uniquely identify the product with a serialized identifier

Read more

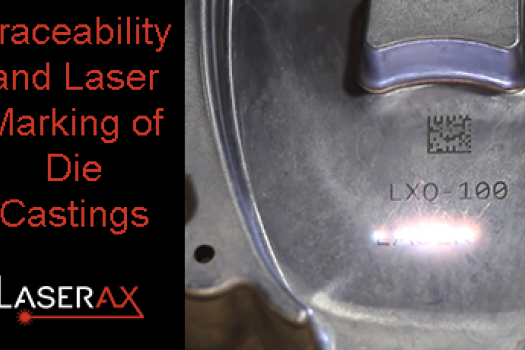

Laser direct part marking on die castings allows improved traceability and provides invaluable information up and down the value chain.

Read more