How It Works: Laser Processes for Marking Metals

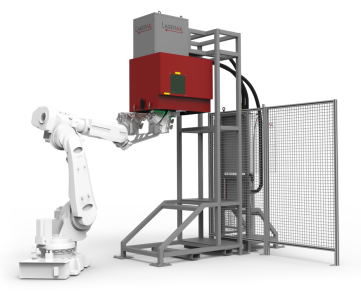

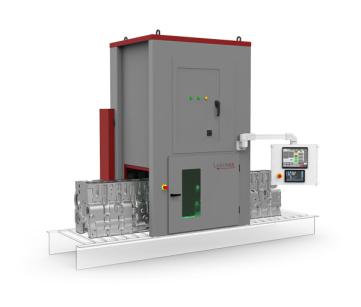

Once you get your machine, it’s already been configured by our experts with a specific marking process. Its configuration is mostly based on the metal being marked. For future applications, the same machine can be configured to mark different metals.

A machine’s configuration depends on its laser parameters. Examples of parameters that can be modified are laser power, movement speed, pulse duration, and number of laser passes. Here are the possible marking processes resulting from these configurations.

Laser Etching

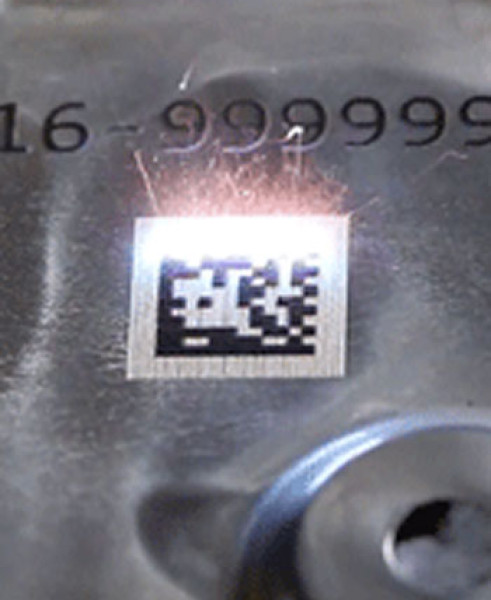

Metal etching machines offer the fastest marking speed possible. For example, Laserax is able to etch high-quality data matrix codes on aluminum parts in just 1.40 seconds (for a 16x16 DMC of 10x10 mm; find out more about marking speeds for aluminum here).

This process is the best choice for most applications, unless you need increased resistance to surface treatments, corrosion, or wear and tear. In those cases, engraving or annealing will be better adapted to your application.

You can laser etch: Steel, Aluminum, Anodized Aluminum, Lead, Magnesium, Zinc

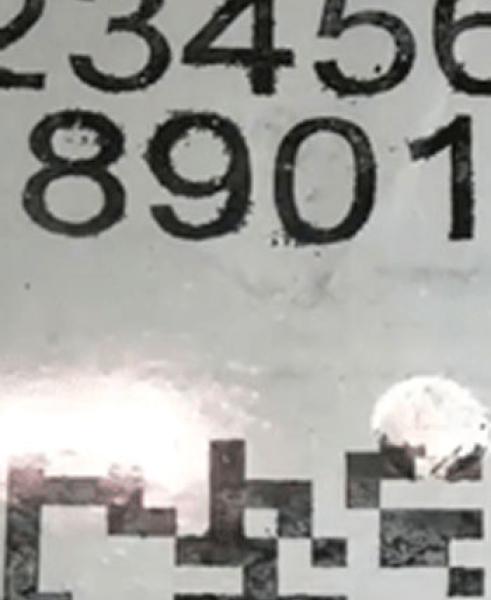

Laser Engraving

Laser engraving machines generate marks that are deep enough to resist abrasion and most surface treatments. When engraving metals with this process, you can implement traceability earlier in the production process. Examples of metal laser engraving are VIN markings and shotblast resistant markings.

You can laser engrave: Steel, Aluminum, Anodized Aluminum (before anodization)

Laser Annealing

Laser annealing is used to avoid any damage to the part surface, as it is the only process that does not use laser ablation. Instead, it triggers a chemical reaction that creates marks under the material’s surface. This method is useful for parts like stainless steel exhaust lines, which must keep a high resistance to corrosion.

You can laser anneal: Steel, Stainless Steel, Chrome Plating

Deep Laser Engraving

As the name suggests, deep engraving creates markings with smooth edges that are much deeper than regular engravings. This process is typically used for applications that have depth and aesthetic requirements. Some examples include logos, stamping plates, and mold inserts. The engraving speed varies based on the laser power, the material, and the line width.

You can deep engrave: Steel, Stainless Steel, Aluminum

Laser Machine FAQs

What’s the difference between CO2 lasers and fiber lasers?

CO2 laser marking machines produce a different wavelength than fiber lasers. As a result, fiber lasers are quite efficient at marking most metal surfaces, whereas CO2 lasers are better at marking non-metal (organic) materials like wood and plastics.

Read more on the subject: CO2 vs. Fiber Laser - Which One Should You Buy?

Can a CO2 Laser Engrave Metals?

CO2 lasers cannot engrave metals, but they can still leave permanent marks. This is because CO2 wavelengths do not react with metal materials. As a result, the surface needs to be covered by a special marking spray that forms a strong chemical bond with the metal when hit by laser light.

Operators need to apply the spray manually and allow it to dry before marking, adding extra steps and consumables to the operation. For these reasons, part manufacturers usually prefer fiber laser engravers, the solution offered by Laserax for metal engraving.

Read more on the subject: How to Choose the Best Fiber Laser Engraver

What’s the difference between laser cutting and laser engraving?

Laser cutting uses laser technology to cut materials whereas laser engraving is focused on marking. Laser cutters use continuous-wave lasers, whereas laser engravers use pulsed laser beams. The engraving process rarely exceeds 100W, but it reaches higher peaks of energy. Laser cutting machines can continuously function at 6,000W of laser power while laser engravers can create peaks of 10,000W.

Should I engrave QR codes or data matrix codes?

QR code laser marking is used in many applications. Yet, data matrix codes offer an important advantage when compared to QR codes. They’re capable of encoding more characters in the same space, which often means faster marking speeds.

Read more on the subject: Data Matrix Codes vs. QR Codes - What Is the Difference?

How much does a laser machine cost?

Many factors affect the price range of a laser machine, such as the laser system, the laser head, the automation level, the laser options, the laser power, and the laser equipment. High-power lasers, for example, are faster but more expensive. Prices also vary from one manufacturer to the other based on several factors, such as the quality of the optical components they use, or the expertise and service they offer.

Read more on the subject: How Much Does a Laser Etching Machine Cost?

How long does it take to mark with a laser?

Industrial lasers can achieve permanent results quickly. In most cases, the difference between one marking application and another is a matter of seconds. The marking time depends on three key factors:

- Material: Engraving a hard material requires more time and energy

- Color: Pitch-black markings take more time than shades of gray

- Power: The more powerful the laser, the faster the marking speed