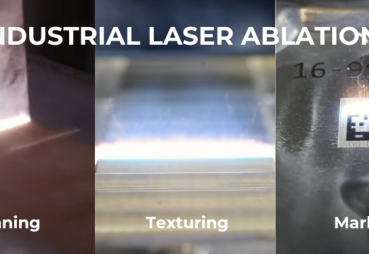

What Is Industrial Laser Ablation?

Laser ablation occurs when a laser beam removes material from a localized area. Used in various industrial applications, this process can create permanent marks (laser marking), remove contaminants and coatings from surfaces (laser cleaning), modify a part’s roughness (laser texturing), cut through a surface (laser cutting) and much more.