Laser Beam Welding Explained

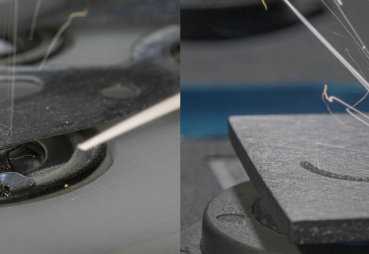

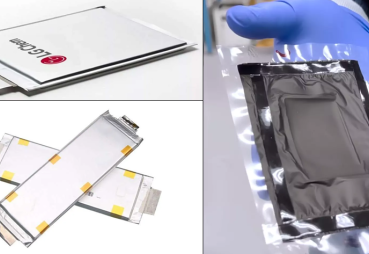

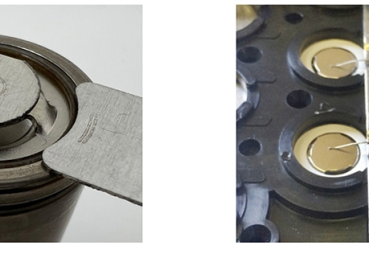

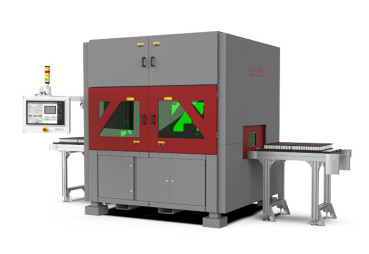

Laser beam welding (LBW) is a precise and efficient method used to join materials through the use of a laser beam. It is known for its accuracy, speed, and ability to work on small, delicate components, making it ideal for industries like electronics, batteries, automotive, and aerospace.