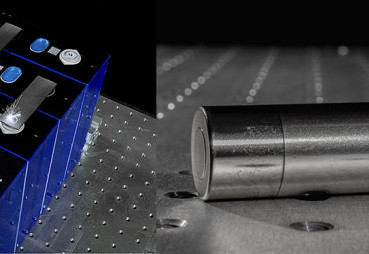

Can Lasers Replace Thermal Spray Masking Tapes and Grits?

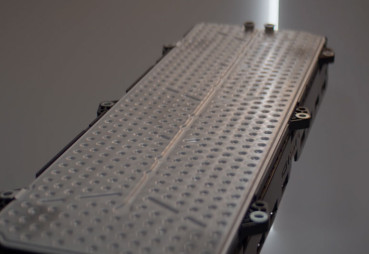

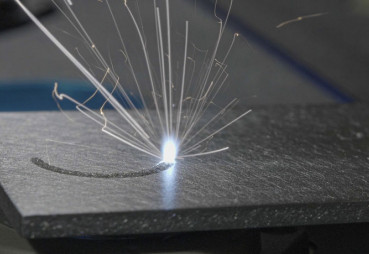

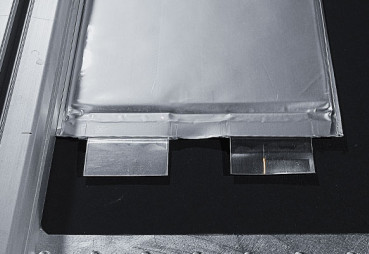

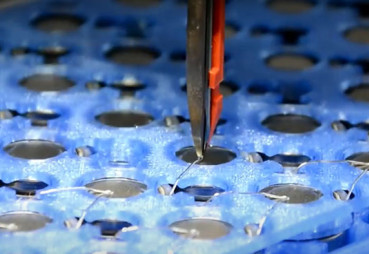

Masking tapes have long been used to prevent specific areas from being spray coated or grit blasted. But did you know that lasers provide a faster and more reliable alternative that’s easier to automate?