Phosphate Coating Removal Without Chemicals

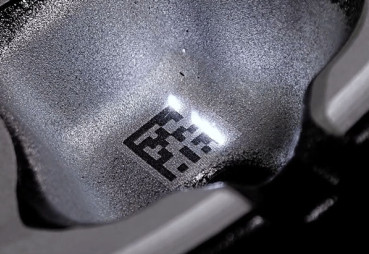

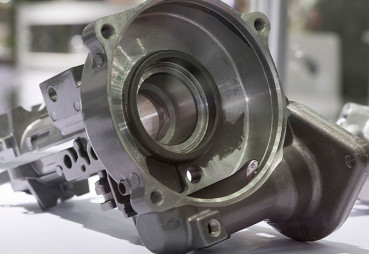

If you’ve ever stripped the phosphate coating off a part, or managed a phosphate conversion coating process, chances are you’ve seen your fair share of chemicals. If you want to get rid of chemicals during phosphate coating removal, laser cleaning may be the solution you’re looking for.